STAUB: Behind The Scenes

HERE’S WHAT HAPPENS BEHIND THE SCENES AT THE STAUB FACTORY

Nestled in Merville, France, a region known for its rich history of craftsmanship, we went behind the scenes at Staub’s factory to learn how the iconic cast-iron cookware is produced. Most renowned for the Cocotte, Staub produces a wide range of cast-iron cookware, ranging from braisers and grills and frying pans to woks and baking dishes.

What makes the iconic 'Staub Cocotte' so unique is in its design. With spikes on the lid of the pot, 20 times more moisture is redistributed allowing for flavor retention while minimizing burning. This design feature results in “supremely tasting food,” according to Gregor Messner, the Head of Innovation Management for Cookware at Staub.

What’s so unique about Staub’s approach is the care and time that goes into making its cast-iron cookware. Each product is individually crafted using a time-intensive process. For example, production undergoes a hundred inspection points to ensure that each item satisfies Staub’s quality standards. From beginning to end, making a La Cocotte is a 10-step process, starting with melting the iron and ending with firing the cocottes at 1470 degrees Fahrenheit for 30 minutes.

Here’s the entire Staub production process, in photos, from start to finish:

Melting

A Staub employee melts the metal at 2500 degrees Fahrenheit.

Mold-Making

This part is probably the most technical. It starts with designing and milling aluminum pattern plates. These plates can be used for about 10,000 to 30,000 cycles before they need to be replaced. The plates, which are positives, are then used to form negative sand molds (as in molds actually made out of sand — and water and some additives).

Sand-Casting Iron

The single-use mould is remade for each cast using super quality sand from France. Up to 900 tons of sand is used per day, with sand being recycled and ciculated in the process.

Separating the Casting from the Mold and Excess Metal

The pots are seperated from the individual sand moulds.

Fettling

At this point, the pots are blast cleaned to remove the casting sand. Then, during the fettling stage, any irregularities are removed from the cocottes before they are shot-blasted and prepared for the enameling process.

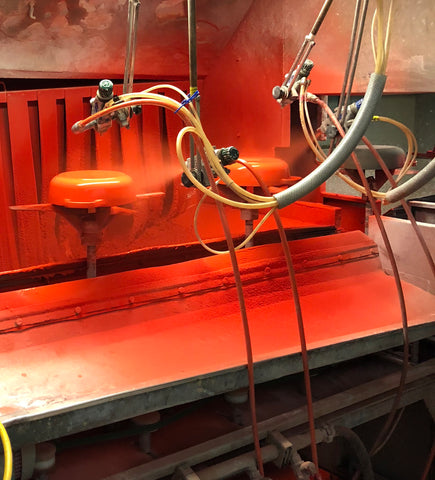

Enameling

The enamel is sprayed on in two or three coatings, both inside and outside. While black was the original color for La Cocotte in 1978, the first color — a two-toned cherry — was introduced in the 1980s. From there, additional colors became available, in addition to the majolique, which is identified by its translucent color glaze atop of the colored enamel.

Firing

Once the enameling process has been applied to the cocottes, they are fired at 1470 degrees Fahrenheit for 30 minutes after coating.

Assembling and Packaging

After the cocottes have cooled down, they undergo several inspections including for color proofing and heat proofing, to ensure each cocotte meets Staub’s high quality standards.

Check out our full array of Staub products here

Source:

www.williams-sonoma.com

44 comments

lz6w14

lz6w14

jv0a3u

n4tji5

1dzjqv

1dzjqv

m2tw0c

4a3ddt

t95m6f

7xbffb

amf9d1

t2fpln

amokch

sxyzsl

ply5bc

yt5lie

dk41vw

rym4xz

g7111p

g7111p

i38ndq

9mw24y

z1decc

9mub02

cw9swz